Save up to two days on truss and frame install*

Partner with Dahlsens for your truss and frame and you could save up to a day in installation time*, thanks to Pryda SpeedTruss™, a game-changing solution for roof truss installation. With SpeedTruss™, prefabricated trusses are supplied with preinstalled tie-down screws that do away with triple grips for a faster, safer and cleaner system. Combine SpeedTruss™ with Pryda Fast Fix Internal Wall Screw and Pryda Framing Screw, and you could save up to two full days installing truss and frame.* Find out more.

Prefabricated truss and frame you can trust

As one of Australia’s largest residential and multi-residential prefab truss and frame manufacturers, with 16 manufacturing sites in operation, you can rely on our team of specialists, ever-expanding technology, network capacity and our ongoing developments to help keep your projects delivered on time and on budget. If you require prefabricated truss and frame in Melbourne, Sydney, Canberra, Gippsland, regional Victoria or New South Wales, the team at Dahlsens has a competitive solution for you.

Save up to two days installing truss and frame from Dahlsens*

![]()

Preinstalled tiedown screws to

replace triple grips.

Internal Wall Screws to replace

L Brackets

Framing Screws replace stud ties when a second

top plate is required

*Time savings are dependent on factors such as the size of the build, number of people installing the truss and frame system, choice of tools and methods of installation.

What builders are saying

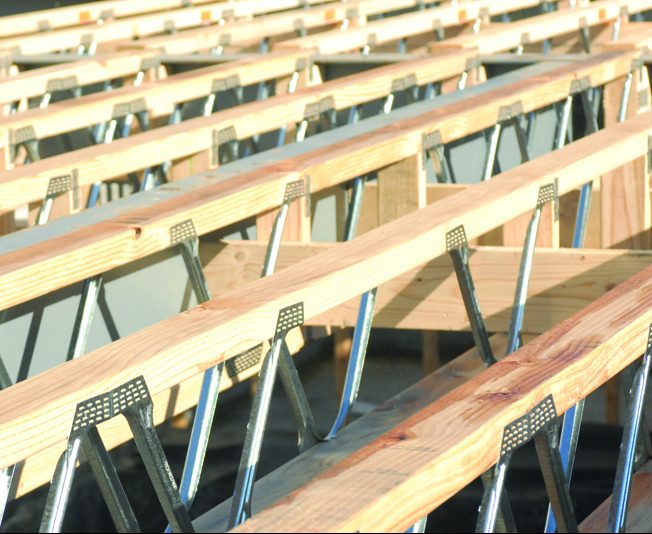

Roof trusses

Save time on site with prefabricated roof trusses from Dahlsens. Delivered to the site, ready to install, timber roof trusses are a cost effective solution for reducing build time and delays on site.

Wall frames

Prefabricated wall frames supplied by Dahlsens offer quality design and maximum efficiency by saving you time onsite. All jobs can be manufactured using treated timber – a benefit builders can sell to their end users.

Flooring systems

Dahlsens offer prefabricated flooring systems which not only speed up installation onsite, but also cater for long spans, cantilevers and depths to suit any loading requirement.

Pryda SpeedTruss™

Pryda SpeedTruss™ is a new and game-changing approach to roof truss design and installation available from Dahlsens. It’s a prefabricated truss system that functions like an assembly kit, incorporating pre-installed screws. The innovation reduces truss installation time by removing temporary fixing, and gets a thumbs up from certifiers for the accuracy it enforces on truss installation.

- Pre-installed screws make installation faster and safer

- Save up to a day installation time

- Does away with triple grips

- Most tie-downs at or below the top plate

- Covered by Producer Statement giving peace of mind for certification

Pryda FastFixTM Internal Wall Screw

FastFixTM Internal Wall Screw (IWS) is an innovative new solution from Pryda, that replaces the traditional and often incorrectly installed L Bracket which connects the bottom chords to wall frames.

A placement guide positions the screw vertically, with the correct off-sets to ensure it is driven up through the vertical centreline of the truss and the wall every time.

- A fast, compliant connection

- Real time savings in installation – up to half a day

- Lines up perfectly every time

- Installed from below the top plate, making it a safer work site

- With the IWS, builders can work just two rungs up a ladder

Partnering with Pryda

Dahlsens chooses to partner with Pryda, which has been at the forefront of the Australian building industry for over 50 years with their unique innovations that strive for safe, fast, smart and efficient manufacturing for builders. Pryda’s engineering software and full range of timber connectors and structural brackets supports Dahlsens to design and manufacture efficient and compliant designs and installation.

Visualise your 2D plan in 3D!

Dahlsens’ 3D View program is accessed via a QR Code that appears on your truss and frame manufactured plans to make it easy to understand the structure in the context of the surrounding space. In addition, 3D View gives you the following:

- A real 3D view of the finished project before lifting a finger

- The 3D model enables the homeowner to get a good understanding of how things will be laid out

- The 3D model can be rotated for different perspectives and to gather additional views

The 3D view can be used before, during and after installation of your frame, floor or truss to give you a better picture of how to start, key intersections and as a checking tool.

Ask for Dahlsens 3D View to be included on your next layout.

Compliance

Our #1 focus is ensuring the product we supply you is compliant with all building codes. Reference guides for installation can be downloaded here:

Benefit from experience,

consider it done

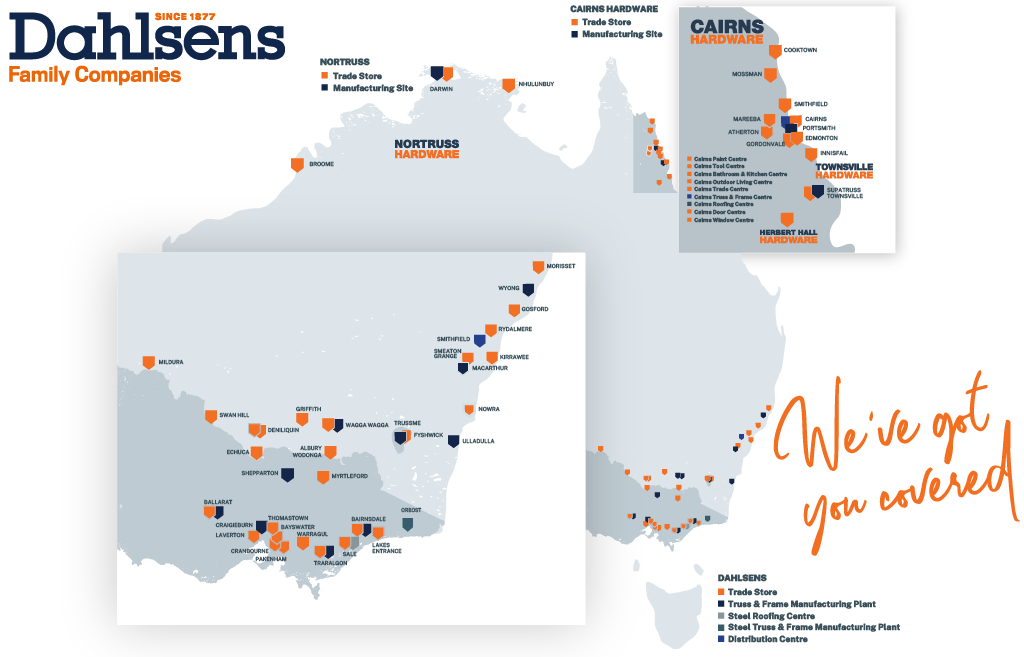

Dahlsens Families Companies is one of Australia’s largest truss and frame manufacturers.

Operating over 70 trade stores, truss and frame and other manufacturing sites across Australia, the business trades as Dahlsens in Victoria, New South Wales and the ACT, Cairns Hardware in far north Queensland, and Nortruss Hardware in Northern Territory and Broome, Western Australia.

Dahlsens is proud to be at the forefront of truss and frame technology that helps you complete quality projects on time and on budget.

Termite treated blue pine

Protecting homes from the inside out, termite treated blue pine gives homeowners a sense of security and reduces the need for regular treatments with costly chemical sprays.

- 25-year warranty against structural termite damage

- Little to no post-construction maintenance

- Safe for homeowners, visitors to their homes and their pets