Spantec is an Australian owned and operated company that has been in operation for over 30 years, manufacturing light gauge steel products for the residential and commercial building industry. Specialising in providing the full solutions including supply, design and engineering of subfloor, deck, and roof structures.

Invented in Australia, Spantec’s flagship product, Boxspan, was the first lightweight steel beam manufactured for use in residential construction. Continuous innovation has seen additional products added, such as EziPier and EziBrace, the adjustable piering and brace systems, and a large range of easy-to-assemble bracketry that ensures Spantec continues to provide not only a full solution but to add value and speed of install to each project.

Spantec’s motto is ‘Making Building Easy’. This does not just stand for the quality Spantec products, but the unmatched service, passion and commitment to each customer.

Spantec brands

Strong yet light

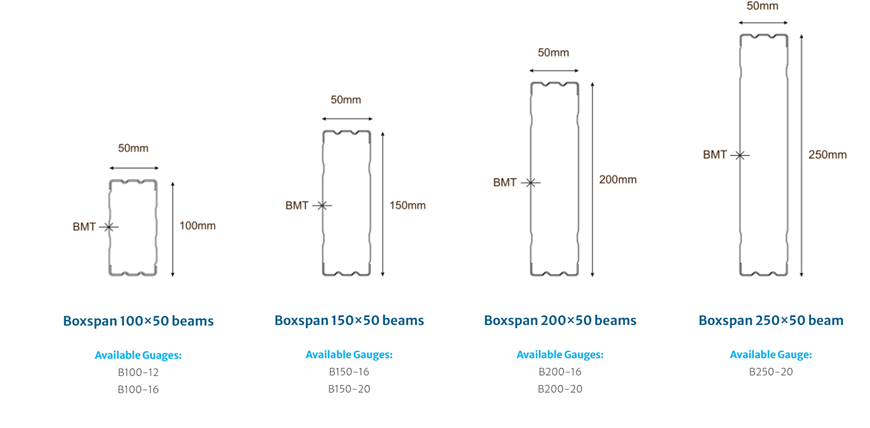

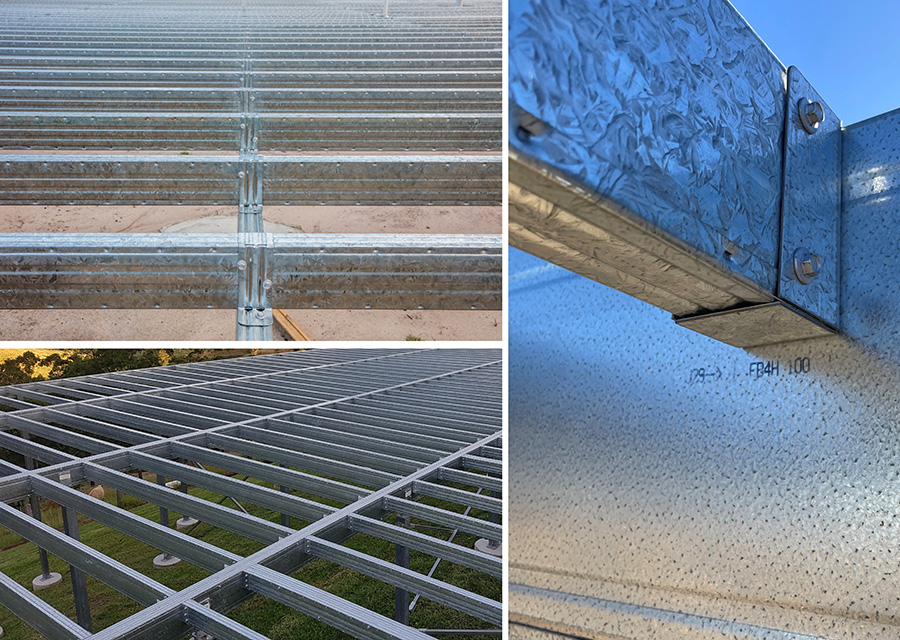

Boxspan is a roll-formed beam manufactured from two C-shape sections of high tensile, Z450 Galvanised coated coil. The two C-section are then mechanically locked together to form a boxed section beam that has an excellent strength versus weight ratio and can be used in multiple different applications.

Key benefits

- Seven sizes available

- Rolled up to 12 metre lengths

- Flexibility in design with a large accessories range

- Great spanning ability

- Straight and true to size

- Strong and durable

- Highest coated beam in its class

- Termite proof

- Perfect solution for flood or bush fire location

Areas of use

- Subfloors

- Decks

- Commercial Floors

- Rafters

- Purlins

- Interior Fit out Raised Floors

- Structural Wall Framing

- Facades

- Skillion Roofs

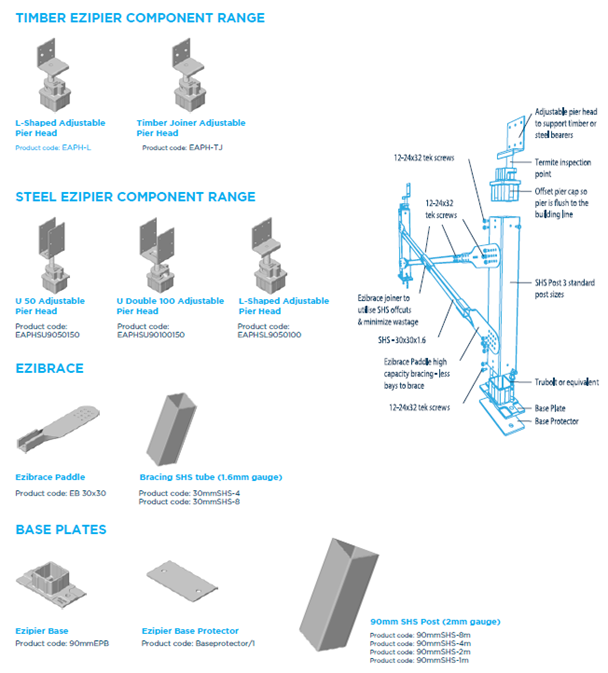

EziPier is a strong galvanised adjustable steel pier system that is fast to assemble, comes in multiple different types and sizes to suit new home or extension sub floors, commercial raised floors, modular construction or re-stumping of an existing structure.

EziPier components; heads and bases, are not only manufactured for the Spantec system but are designed to work with multiple different product types in the market whether it’s timber or steel.

With an extensive range, EziPier matched with EziBrace provides the best premium foundation supports in the market and is fast becoming the tradie choice when building elevated floors.

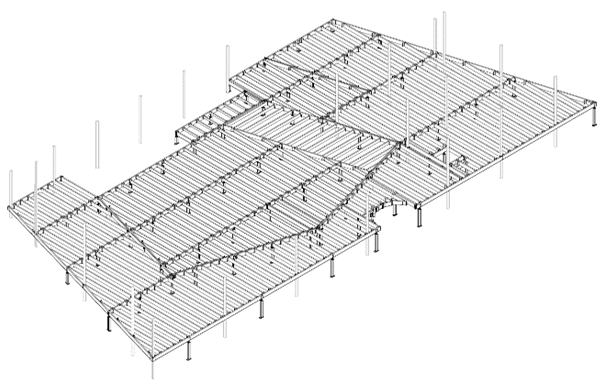

Supply, design and engineering service delivered direct to your site in a cut to size kit format

Endless design opportunities with Spantec’s full product range

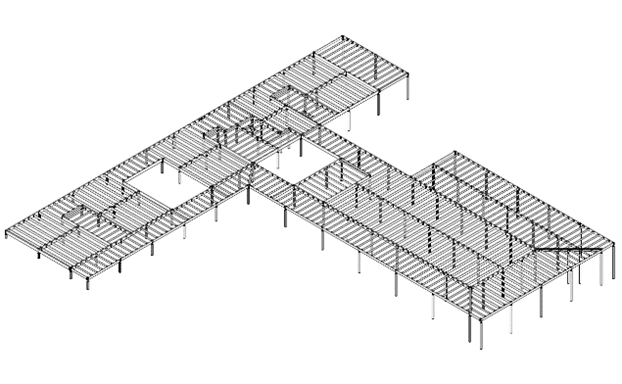

Whether it’s a new home, extension, deck or a large commercial project, Spantec designs, engineers and provides a full cut-to-size kit system manufactured to your requirements. It then arrives on site to seamlessly fit together, speed up the build and provide a solid foundation for your new structure.

Benefits

- Subfloor or decks up to 6 metres in the air can be designed and engineered using Spantec’s full design and engineering offer

- Footings, bracing, and floor frames can be engineered

- Everything arrives onsite cut to size

- Every beam is labelled and corresponds back to the construction drawings

- Each builder receives a full set of construction drawings, custom designed to suit that exact project

- Every bracket and fixing provided, saving time sourcing them yourself

- Adjustable EziPiers supplied with every kit

- Smart bearers, our innovative bearers come pre punched with joist locations

- Set downs, wrap around decks, curves, and angles all possible with our large bracket range

Spantec FAQs

In what areas can Spantec materials be effectively used?

Spantec materials are highly versatile and can be used in a variety of construction applications, including:

Residential Projects: For building floors, roofs, and frames, offering strength and durability.

Commercial Projects: Ideal for warehouses, retail spaces, and office buildings due to their structural integrity and cost-effectiveness.

Agricultural Buildings: Suitable for sheds and barns where high-performance materials are required for long-term use.

Industrial Structures: Spantec materials are great for use in heavy-duty applications that require high strength.

Are there custom design options available with Spantec systems?

Yes, Spantec offers flexibility with custom design options. Their systems can be tailored to meet specific project needs, whether it’s adjusting dimensions, load-bearing capabilities, or material finishes. This customisation allows for a high degree of adaptability, ensuring that Spantec materials can accommodate a wide range of architectural designs and structural requirements.

What specific innovations set Spantec materials apart from traditional construction materials?

Spantec materials are distinguished by:

Lightweight Design: Compared to traditional materials like timber and steel, Spantec products are lighter, reducing labor costs and easing handling.

Superior Strength: Advanced engineering ensures that Spantec systems provide enhanced strength-to-weight ratios, improving overall structural performance.

Durability and Longevity: Made from corrosion-resistant materials, Spantec systems offer long-term resilience, reducing maintenance and replacement costs.

Ease of Installation: Their pre-fabricated kits streamline the construction process, minimising on-site labor and construction time.

Can Spantec materials be used for both residential and commercial projects?

Yes, Spantec materials are ideal for both residential and commercial applications. For residential projects, they can be used for floors, roofs, and framing. In commercial projects, their high strength and ease of assembly make them perfect for industrial buildings, warehouses, and large-scale retail or office spaces. Spantec’s versatile systems can be adapted to meet the specific demands of any type of project.

How does the delivery of Spantec materials in a kit format streamline the construction process?

Spantec’s kit delivery system simplifies construction by providing pre-assembled, easy-to-transport components. This reduces the need for on-site fabrication and minimises waste. The kit format:

Reduces Labor Costs: Pre-cut and pre-fabricated parts save time during assembly.

Improves Accuracy: With materials tailored for the project, there’s less room for error.

Increases Efficiency: The ready-to-use components speed up the building process and reduce the overall project timeline.

How do I calculate the quantity of Spantec materials needed for my project?

To calculate the required quantity of Spantec materials:

Consult Project Plans: Use architectural or engineering drawings to understand the dimensions and structural needs.

Material Specifications: Refer to Spantec’s material guidelines to determine the quantity of components required (e.g., beams, trusses, flooring panels).

Estimate Using a Calculator: Spantec often provides online calculators or tools to help you estimate material quantities based on your project’s scale and specifications.

Professional Support: Spantec’s team can assist with accurate calculations based on your project requirements, ensuring you order the right amount.