For all your laminated veneer lumber (LVL), glue laminated timber (GLT) and engineered timber needs, Dahlsens is here for you. We have access to a wide range of solutions, in a variety of species and sizes to suit your project needs.

LVL

What is LVL-engineered timber?

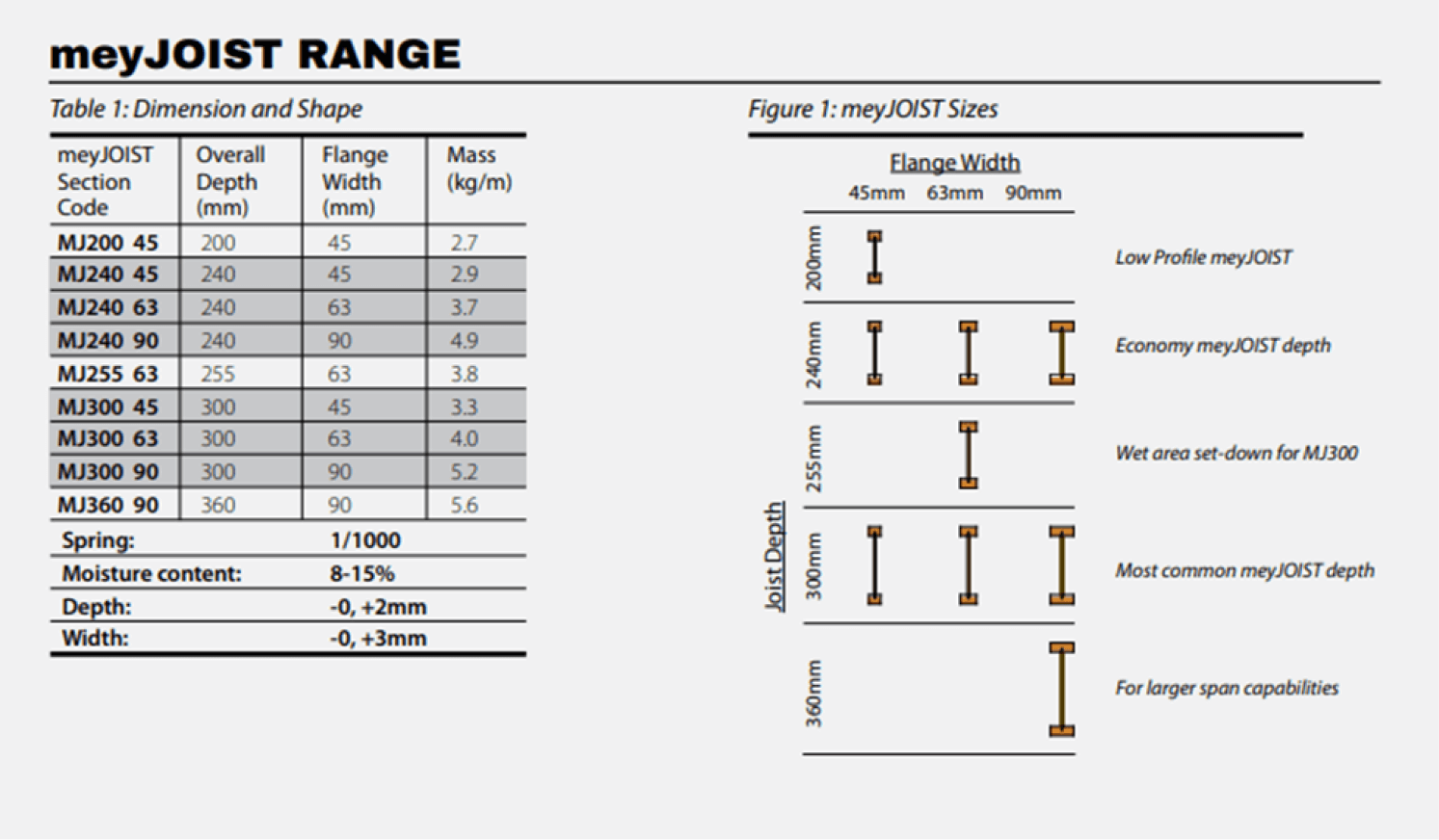

Made from strips of timber veneer laminated together, LVL is a high-strength structural timber product available in a range of sizes, grades and thicknesses.

Ideal for applications such as lintels, rafters, beams, floor joists and framing, LVL’s strength is able to stand up to heavy loads.

Our LVL suppliers

Rest assured, when you purchase LVL from Dahlsens you can be confident that you’re buying a compliant product, supplied with the correct certifications and documentation to back it. To ensure the integrity of our LVL, Dahlsens chooses to partner exclusively with Australia’s major LVL importers, including Meyer Timber, Tilings, ITI and Wesbeam, who are trusted for their rigorous due diligence processes.

Types of Engineered LVL timber products available

LVL Framing

Reliable and strong, LVL is increasingly becoming a popular choice for structural framing. Unlike natural timber, engineered timber is less likely to warp or bend, reducing the need for straightening walls after framing is complete.

LVL is also termite resistant H2S, which makes it a great option for homeowners seeking peace of mind.

LVL framing sizes and grades

| Grade | Size | Width | Length | Increments |

| LVL 10 | 90 | 35 | 2.7 | |

| LVL 10 | 90 | 45 | 2.7 | |

| LVL 12 | 90 | 35 | 2.7 – 6.0 | In 600mm increments |

| LVL 12 | 90 | 45 | 2.7 – 6.0 | In 600mm increments |

meyFrame12 LVL Framing

meyFrame12 LVL Framing offers the straightness of LVL for easier pre-sheet checks and is perfect for high raking walls. It delivers superior performance compared to MGP12. Available in designIT and all nailplate company software, meyFRAME12 is sourced from legally harvested raw materials and features H2 termite protection and a moisture-resistant barrier.

Featuring:

- The straightness of LVL for easier pre-sheet check

- Perfect for high raking walls

- Superior performance to MGP12

- Available in designIT and all nailplate company software

- Sourced using legally harvested raw material

| Size | Width | Lengths |

| 90 | 35 | 2.4,2.7,3.6,4.8,5.4,6.0 |

| 90 | 45 | 2.7,3.6,4.8,5.4,6.0 |

LVL beams and lintels

The improved strength of LVL when compared to solid timber means it can be used in a wider range of structural applications such as lintels, beams, rafters and joists. LVL timber beams can be supplied to any length up to 12m and are also less prone to warping than long lengths of timber.

LVL supplied by Dahlsens is also treated with a short-term water repellant designed to prevent water damage during construction. It can also be treated with optional H3 treatments to prevent decay.

Dahlsens only partners with trusted suppliers for LVL compliant to Australian Standards including Meyer Timber for MeySpan, Tilings for SmartLVL and ITI for Specbeam.

LVL beam sizes and grades

| Grade | Depth | Width | Length |

| LVL13 | 90 | 63 | 1.2-12.0M |

| LVL13 | 150 | 45 | 1.2-12.0M |

| LVL13 | 150 | 63 | 1.2-12.0M |

| LVL13 | 200 | 45 | 1.2-12.0M |

| LVL13 | 200 | 63 | 1.2-12.0M |

| LVL13 | 240 | 63 | 1.2-12.0M |

| LVL13 | 300 | 45 | 1.2-12.0M |

| LVL13 | 300 | 63 | 1.2-12.0M |

| LVL13 | 300 | 75 | 1.2-12.0M |

| LVL13 | 360 | 45 | 1.2-12.0M |

| LVL13 | 360 | 63 | 1.2-12.0M |

| LVL13 | 400 | 45 | 1.2-12.0M |

| LVL13 | 400 | 63 | 1.2-12.0M |

| LVL13 | 400 | 75 | 1.2-12.0M |

| LVL13 | 450 | 63 | 1.2-12.0M |

| LVL14 | 90 | 45 | 1.2-12.0M |

| LVL14 | 120 | 45 | 1.2-12.0M |

| LVL14 | 140 | 45 | 1.2-12.0M |

| LVL14 | 190 | 45 | 1.2-12.0M |

| LVL14 | 240 | 45 | 1.2-12.0M |

LVL lengths go up in 300mm increments up to 9m and 600mm increments 9.6m to 12.0m.

LVL Formwork

Dahlsens can supply LVL formwork for use in concrete construction applications. LVL is ideal for use in formwork as the cross lamination of the layered veneers reduces the effects of cupping in high moisture environments. Produced from sustainable timber, and harvested from certified plantations, LVL is not only a straight and true, uniformly consistent edging, it is also an environmentally friendly composite timber product.

Dahlsens supplies LVL formwork brands Smart Edge Form from Tilling and Edgeform from Carter Holt Harvey.

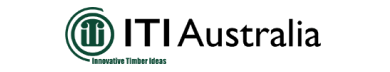

I-Joists

I-Joist are an engineered joist, manufactured with laminated veneer lumber flanges top and bottom, joined with an oriented strand board (OSB) web. Supplied by Dahlsens and primarily used for floor applications, I-joists are a cost effective and lightweight solution. Available in long lengths, they are lightweight, easy to install and have generous allowances for wiring, plumbing, and air conditioning ducting. I-joists supplied by Dahlsens are also supplied with H2S treatment for termite protection.

Looking for a flooring system for your next project? Our team can support you. We can connect you with experienced engineering support through Meyer Timber, trusted I-joist and LVL supplier to Dahlsens. We can also arrange pre-cut holes in your I-joist flooring system for your convenience.

Dahlsens supplies cost effective, high performance I-Joist products including Meyjoist and SmartJoist. Available in heights from 200 – 400mm as well as a 255mm Wet Area Set-Down joist option, i-joist products are suitable for most residential structures.

Glue Laminated Timber

Glue laminated timber (GLT) is a solid wood alternative to engineered timber. Unlike LVL where veneers of timber are laminated together, GLT is manufactured from solid lengths of timber glued together. The renowned natural strength of timber is enhanced with the glue laminating process, resulting in a product ideal for beams, bearers, joists and posts.

GLT is a practical alternative to steel, being a fraction of the weight with the advantage of being easily cut, notched, or drilled on site.

Glue laminated species

Dahlsens can access glue laminated timber in pine as well as a range of other species and sizes to suit your project. GLT beams are available as straight, curved and shaped to achieve unlimited design flexibility for timber construction.

Hyne Lumber Glue Laminated (LGL)

LGL is an acronym for ‘Lumber Glue Laminated’ — a solid wood alternative to LVL beams, manufactured by Hyne Timber. LGL is straight, stable in outdoor environments, and ideal in applications where nail-holding strength is an absolute priority.

- H3 treated for indoor and outdoor, above ground applications.

- Ideal for lintels, joists, and bearers, LGL is an alternative to LVL.

- Engineered to not only hold high loads, but also a nail, making it easy to work with on site.

- LGL is a fraction of the weight of steel with the advantage of being easily cut, notched, or drilled on site.

Hyne Lumber Glue Laminated (LGL)

Hyne Beam 15

Beam 15 is a high-performance structural product that’s engineered to handle long spans and critical loads. Hyne’s strongest softwood beam, they have been rigorously tested for quality assurance.

- Available H2 or H3 treated for indoor and outdoor, above ground applications in Australia

- Beam 15 is the perfect alternative for LVL, Steel or GL17 beams, with enhanced supply

- Ideal for lintels over large window and door openings, garage openings or roof beams, where spans over large spaces are dictated by design

- Appearance ‘Grade A’ is made to order and intended for use in applications where appearance is important and clear or painted finishes are used. All surface voids are therefore filled or repaired. Unless otherwise specified, the surfaces are sanded to a minimum 60 grit finish

Hyne Beam 21

Made from sustainably managed Australian hardwoods, Beam 21 asserts itself in a crowd with its uniquely Australian looks combined with pure brawn.

- Available H2F treated for indoor, above ground applications in Australia

- Made from responsibly sourced mixed Queensland hardwoods, Beam 21 is a design feature

- Ideal for high load applications where spans over large spaces are dictated by design

- All Beam 21 beams are produced from sustainably sourced iconic Queensland hardwood and carry Responsible Wood (PEFC) chain-of-custody certification

- Appearance ‘Grade A’ is made to order and intended for use in applications where appearance is important and clear or painted finishes are used. All surface voids are therefore filled or repaired. Unless otherwise specified, the surfaces are sanded to a minimum 60 grit finish

Magna Merbau Glulam

Combining the strength of glue laminated timber with the tropical appeal of merbau, Magna Glulam is available in variety of sizes for a number of external and internal applications.

Made from sustainable supplies of Merbau (Kwila) timber, Magna utilises off-cuts and finger-jointed technology to make the resource go further. The manufacturer is so confident in the laminating process, that it is backed by a 15 year warranty and has a BAL rating of BAL 29.

Magna Merbau Glulam sizes

| Product | Grade | Size | Lengths |

| Magna Glulam Posts | GL13 | 90×90 | 2.4, 2.7, 3.0, 3.6, 4.8, 5.4, 6.0, 7.2 |

| GL13 | 115×115 | 3.0, 3.6, 4.8, 5.4, 6.0, 7.2 | |

| GL13 | 140×140 | 3.0, 3.6, 4.8, 5.4, 6.0, 7.2 | |

| GL13 | 190×190 | 3.0, 3.6, 4.8, 5.4, 6.0 | |

| Magna Glulam Solid Face Posts | GL13 | 140×140 | 2.7, 3.0, 3.6 |

| GL13 | 190×190 | 2.7, 3.0, 3.6 | |

| Magna Glulam DAR Rafters, floor joists, rails and other | GL17 | 90×42 | 3.6, 4.8, 5.4, 6.0 |

| GL17 | 140×42 | 3.6, 4.2, 4.8, 5.4, 6.0 | |

| GL17 | 190×42 | 4.2, 4.8, 5.4, 6.0, 7.2 | |

| GL17 | 240×42 | 4.2, 4.8, 5.4, 6.0, 7.2 | |

| GL17 | 290×42 | 4.8, 6.0, 7.2 | |

| Magna Glulam Beams | GL17 | 140×65 | 4.8, 5.4, 6.0, 7.8 |

| GL17 | 190×65 | 4.8, 5.4, 6.0, 7.8 | |

| GL17 | 240×65 | 4.8, 5.4, 6.0, 7.8 | |

| GL17 | 290×65 | 4.8, 5.4, 6.0, 7.8 |

LVL-engineered timber FAQS

What is LVL Timber?

LVL, or Laminated Veneer Lumber, is an engineered wood product that has revolutionised the construction industry. It’s manufactured by bonding together thin wood veneers under heat and pressure, with the grain of each layer running in the same direction. This process results in a strong, stable, and uniform product that outperforms traditional solid timber in many aspects. LVL is preferred over traditional timber due to its superior strength-to-weight ratio, consistency in quality, and ability to span longer distances without sagging. Its engineered nature allows for precise manufacturing, reducing waste and improving overall efficiency in construction projects.

What are the benefits of using LVL timber?

Durability and Strength: LVL timber boasts exceptional strength and durability, often surpassing that of solid wood of similar dimensions. Its layered construction distributes stress more evenly, reducing the likelihood of warping or twisting.

Consistency and Reliability: Unlike natural timber, which can have knots and inconsistencies, LVL provides a uniform product with predictable performance. This consistency makes it easier for architects and engineers to design structures with confidence.

What can LVL timber be used for?

LVL timber is extensively used in both residential and commercial construction. In residential projects, it’s commonly used for:

- Beams and headers

- Floor and roof systems

- Wall studs in load-bearing walls

In commercial construction, LVL is often employed in:

- Large-span roof trusses

- Structural framing for multi-story buildings

- Formwork for concrete structures

Warranties

Here at Dahlsens, we take pride in maintaining close relationships with our suppliers. In the unlikely event that you experience an issue with your products, we’ll take care of the warranty process for you. Simply let us know about your issue, and we’ll coordinate a resolution with the supplier on your behalf.